Smart Factory Spreading Project

Improving the competitiveness of manufacturing innovation by supporting the construction, upgrading, and maintenance of various types of

smart factories suitable for small and medium-sized enterprises' manufacturing sites

| Business name | Support Type | Contents of application | Amount of government support | Recruitment period | |

|---|---|---|---|---|---|

| Smart Factory Deploying and upgrading |

Foundation | Support for automation equipment, controllers, sensors, etc. necessary to build and build smart factory solutions (solution linkage) that apply advanced technologies such as IoT, 5G, big data, AR·VR, AI, and cloud to improve product design and production processes. | half a billion won | (The first) 1.17~2.22 (Secondary) 6.1~6.30 | |

| advancement1 | 200 million won | ||||

| advancement2 | Support deployment to improve utilization and level of smart factories by applying artificial intelligence solutions | 400 million won (15 companies in total) |

1.17~3.8 | ||

| Specialized by industry | Foundation |

Support for establishment of automation equipment, controllers, sensors, etc. linked to specialized solutions and solutions by manufacturing process (industry) *Select an operating institution first and then recruit a demand company |

half a billion won | 1.17~2.22 | |

| advancement1 | 200 million won | ||||

| Check smart factory level |

Objectively diagnose a company's manufacturing level, present guidelines for advancement, and provide confirmation *Select confirmation agencies first and then recruit participating companies. |

Full support for level verification costs (KRW 1 million) | (Confirmation Agency, etc.) 1.17-2.7 (Participating Companies) Occasionally (3.2~) |

||

Companies based in Gyeongsangnam-do (20% support fund, up to 40 million won) and companies based in Gyeongsangbuk-do

(10% support fund, up to 20 million won) will be paid separately.

Companies based in Gyeongsangnam-do (20% support fund, up to 40 million won) and companies based in Gyeongsangbuk-do

(10% support fund, up to 20 million won) will be paid separately.

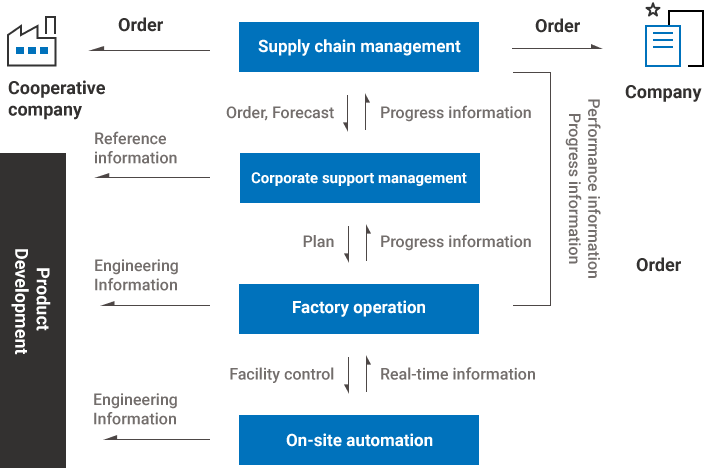

| Sortation | On-site automation | Factory operation | Corporate resource management | Product development | Supply chain management |

|---|---|---|---|---|---|

| advancement | LOT/LOS CPS on the foundation | on the Internet space Business CPS Network collaboration |

|||

| LOT/LOS | LOT/LOS Big Data Driven Diagnostics and Operations |

Big Data / Design.Development Virtual Simulation/3D Printing |

|||

| Medium level | Facility control automation | Real-time factory control | Integration of factory operations | Reference information/technical information Automate creation and connection |

Multivarious Development Cooperation |

| Medium level1 | Automatic aggregation of facility data | Real-time decision making | Integration between features | Reference information/technical information development and operation |

Multivarious Development Cooperation |

| Basic level | Automate performance aggregation | POP | Management function-oriented individual operation | CAD Manage Use Projects | Depend on a single parent company |

| ICT Not applied | Manual work | Manual work | Manual work | Manual work | Telephone and Email Collaboration |

Through MES system construction, production information management, logistics management, quality management, facilities management are realized to provide on-site direct support information, facilitate on-site flow, and provide necessary information (history, statistics, analysis) in a timely manner.

| “ Building an MES System ” Increase productivity, reduce costs, improve quality |

||

|---|---|---|

| Centralize logistics and information Management of production progress information Process Quality Management |

Bad PPM management LOT Tracking Management productivity Production performance management Management of operation management Inactive management Facility efficiency management |

sharing of resources/information operational convenience Increased utilization Productivity, quality improvement |

| “ On-site improvement ” Rapid data collection (defective information, man-hours, non-operation management, facility efficiency, LOT tracking) |

||

Check manufacturing and additional points

Determining the desired level

Receipt of Support