LOT Tracking Management System

Lot tracking management system for raw material forwarding management and production history tracking management is a process production performance including raw material order, warehousing, import inspection, return, import management, and process forwarding management.It should be supported to operate with movement, quality control, etc. Most companies operate MES systems, Lot tracking management systems, and WMS systems separately rather than integrated within the ERP system. However, in this case, complex interworking problems between multiple systems must be supported, and if problems occur in future operations, all systems must be checked, so maintenance is very difficult due to difficulties in identifying the cause. To address these challenges, deploying ERP system DB to support Lot management from the time of process design can provide many benefits for both business and administrators.

Lot Tracking Management Process Overview Improving the raw material ordering and receiving process is essential as a prerequisite for introducing Lot tracking management. An identification table management system that can be applied with PDA or Barcode must be introduced, applied to material ordering and input management processes, and support forward and reverse lot tracking management in production process performance management. Shipping management for sales should also support the application of various processes to respond to shipment, return, and bring-in. Only through this construction process do materials import and export and inventory management based on thorough lot management, process lot tracking management, product warehousing, and shipment.Carry in and manage warehouse inventory efficiently.

-

Work Instruction Establishment (APS)Material input registration, item standard information registration, company information registration

-

Production historyMaterial receiving registration, material input registration, production performance registration, shipment performance registration, Lot Tracking

-

Enter input materialsInquiry of material receiving details, inquiry of material input details, inquiry of production performance, inquiry of shipping details

-

Information for inspectionUser group and user registration, program information registration, user group authorization information registration, user personal authorization information registration

-

MonitoringProduction performance monitoring, shipment details monitoring

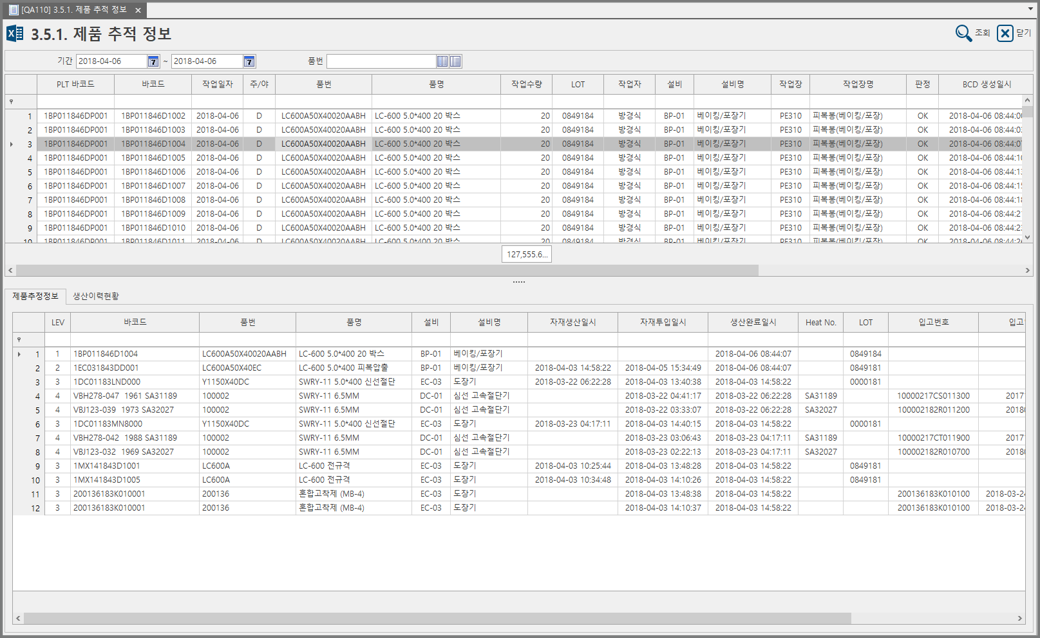

Product Tracking Information

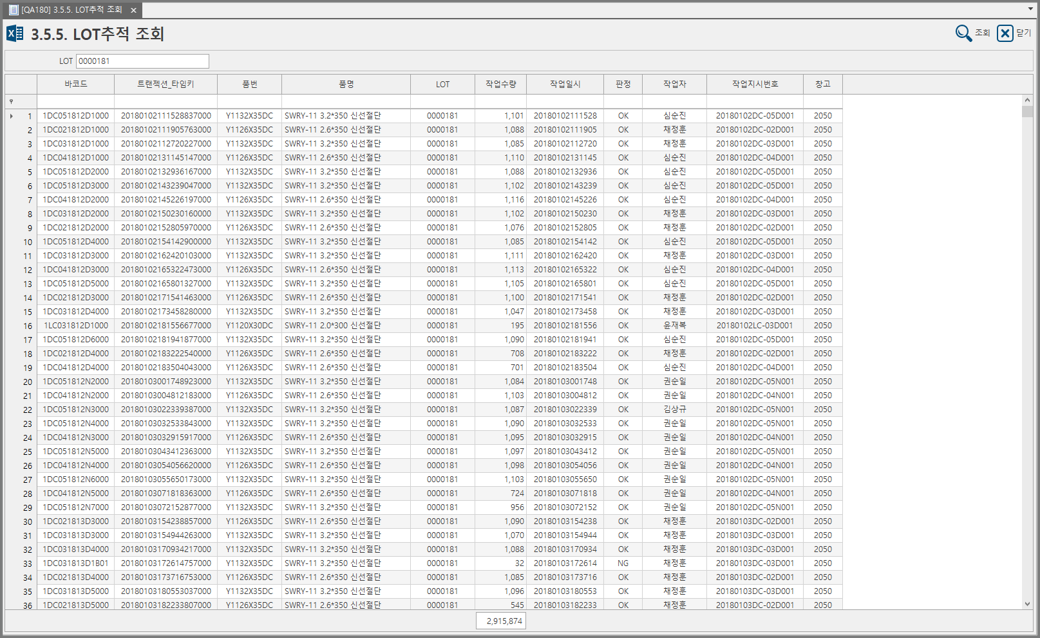

LOT tracking inquiry

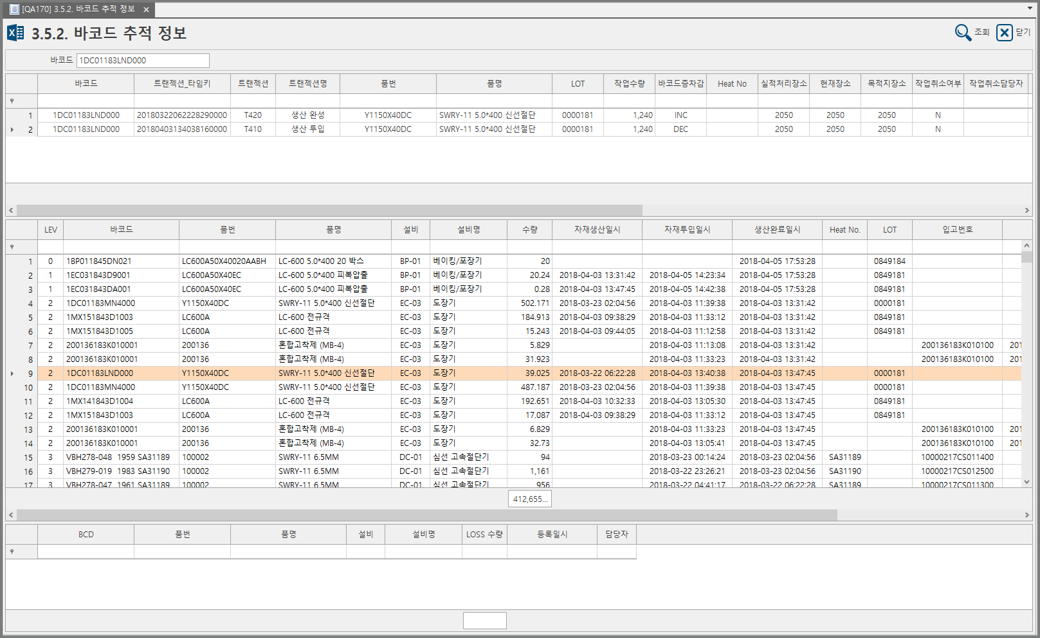

Barcode Tracking Information

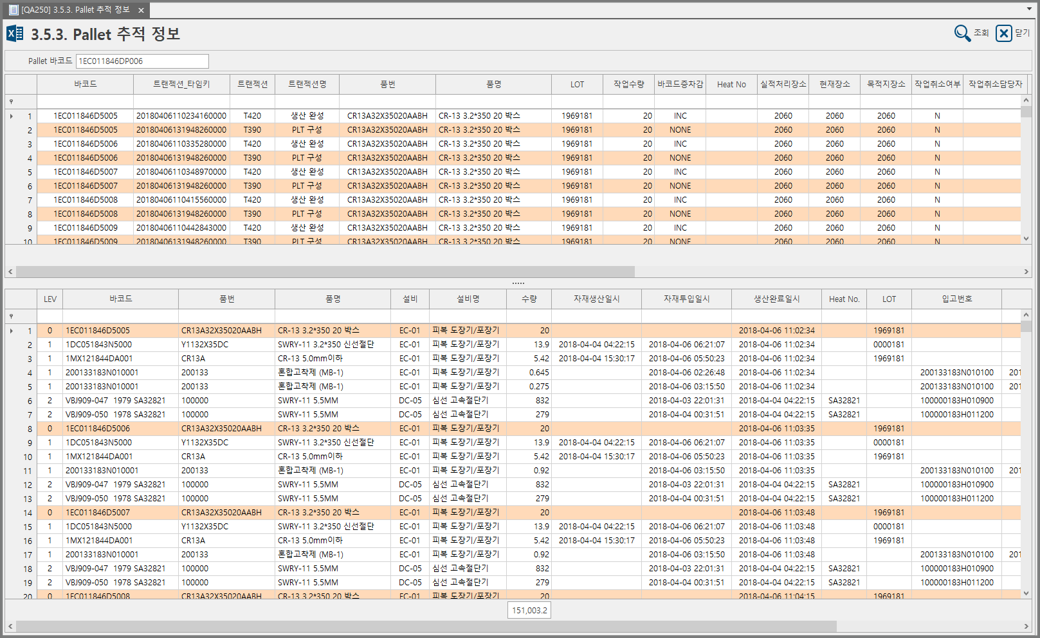

Pallet Tracking Information