MES/POP

Integrated Production Process Management System (MES) that incorporates automation technology, starting with the introduction of raw materials based on the products ordered and production plans. Instruct the execution department to carry out optimal production activities until the shipment stage of semi-finished and finished products, and perform facility conditions, optimization, It collects quality information, semi-finished products, and production progress in real time and provides information on early warning and decision-making for action in case of problems.

-

- Inventory uncertainty

- Sharing real-time production information

Facility utilization

-

- Original Materials

Re-purchase - Quality Improvement Effects

Delivery Rate Improvement (Transparent Production Information)

- Original Materials

-

- Material/Product

Hard to Determine Location - Real-time tracking of production information

Quality and defect information

- Material/Product

-

- Production work information

Unmatched - Real-time tracking of production information

Building a production information infrastructure

- Production work information

| Business Management Aspects | Production/Management Aspects | Customer Service Aspects |

|---|---|---|

| Sharing Real-Time Production Information | Real-time Tracking of Production Information | Enhancing customer service support (reducing customer inquiries, complaint handling) |

| Building a Production Information Infrastructure Foundation | Quality and Defective Information | Quality Improvement Effect |

| Worker Performance Processing in Real-Time | Facility Operation Rate | Delivery rate improvement (transparent production information) |

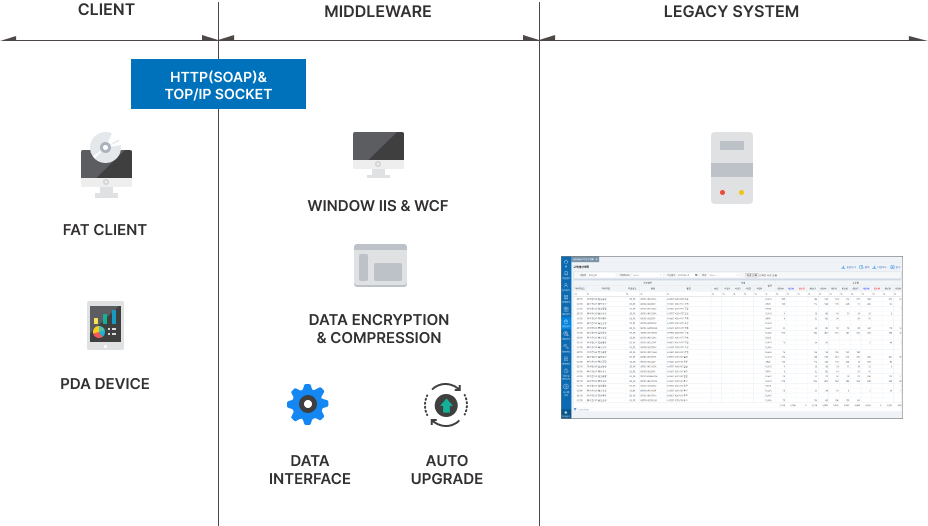

Based on WCF service, the MES package is designed for offices, homes, domestic and international business trips, etc. System is ready for easy installation by administrators and users Provides a web page. Package configurations include administrator programs, field collection POP, PDA programs, It consists of a smartphone and a monitoring program.

MES SERVER

In order to standardize reference information, ensure consistency of information, and prevent user errors, the use of barcodes in materials, Logistics management from production to product warehouse management is the scope of construction, and logistics information tracking and rework/stock information are established in a real-time monitoring environment.

| Material Management | Process Management | Sales Management | Quality Management | Installation/Tool Management | Mold management |

|---|---|---|---|---|---|

| Receiving | Input Performance | Receiving | Inspection Items | Equipment Card | Mold Card |

| Locating | Issued separately | Locating | Import Inspection | Preventive Inspection | Location Management |

| Label Issuance | Production performance | Inventory | Soonhee Inspection | Repair History | Management of water repellent |

| Inventory | Outdoor Management | Shipping Plan | Delivery Inspection | Advice Management | Inspection Management |

| Delivery | Packaging Management | Delivery | Process capability | Chi Tool Management | Repair History |

| Basic Information Management | System Management | ||||

|---|---|---|---|---|---|

| Product Number Master | Workshop Master | Nonconformity code | Terminology Master | Menu Master | User Master |

| Company Master | Process Master | Nonoperation Code | Common Code Master | Department Master | Permission Master |

| Warehouse Master | Inspection Items | Process BOM Information | Screen Master | Employee Master | / |

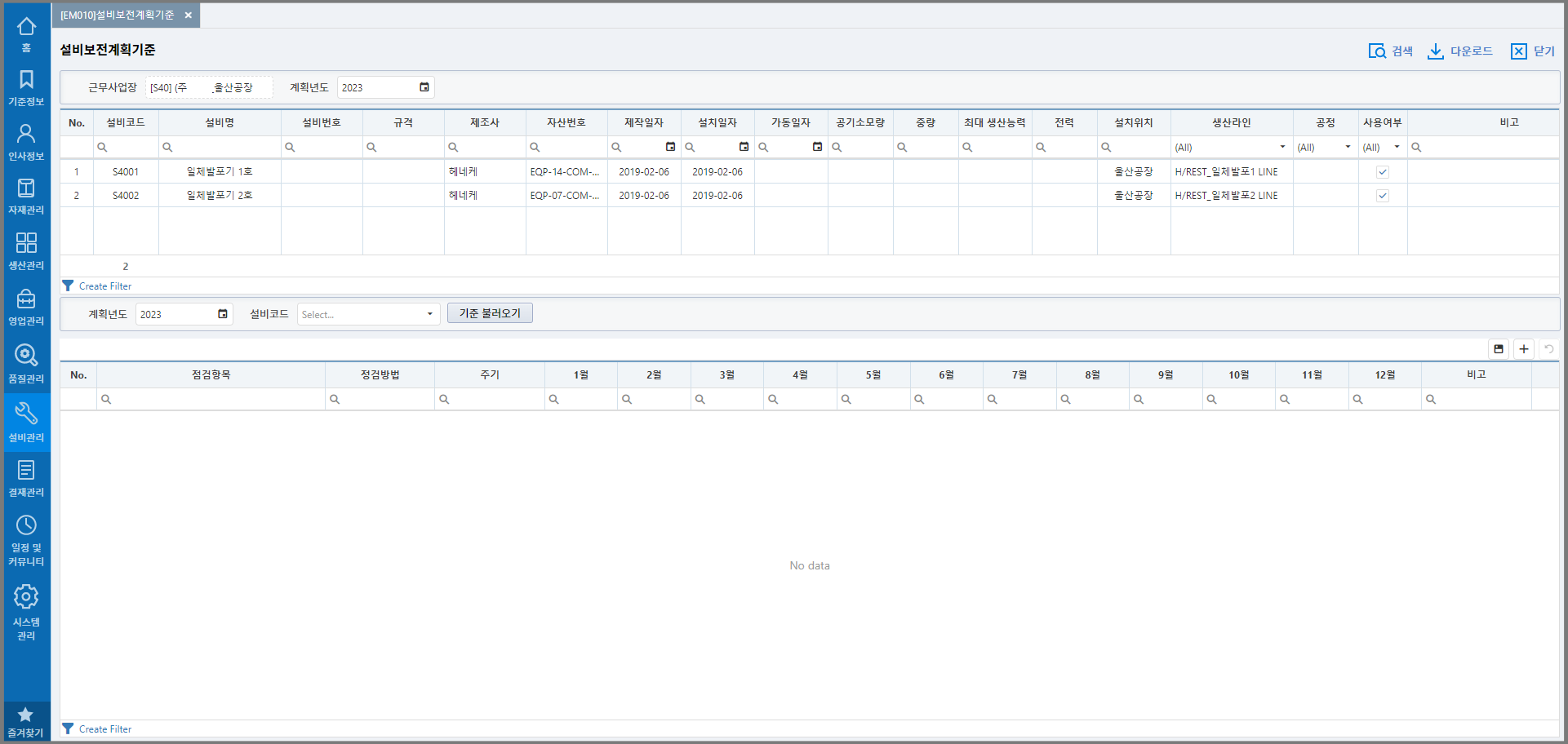

Facility maintenance plan standard

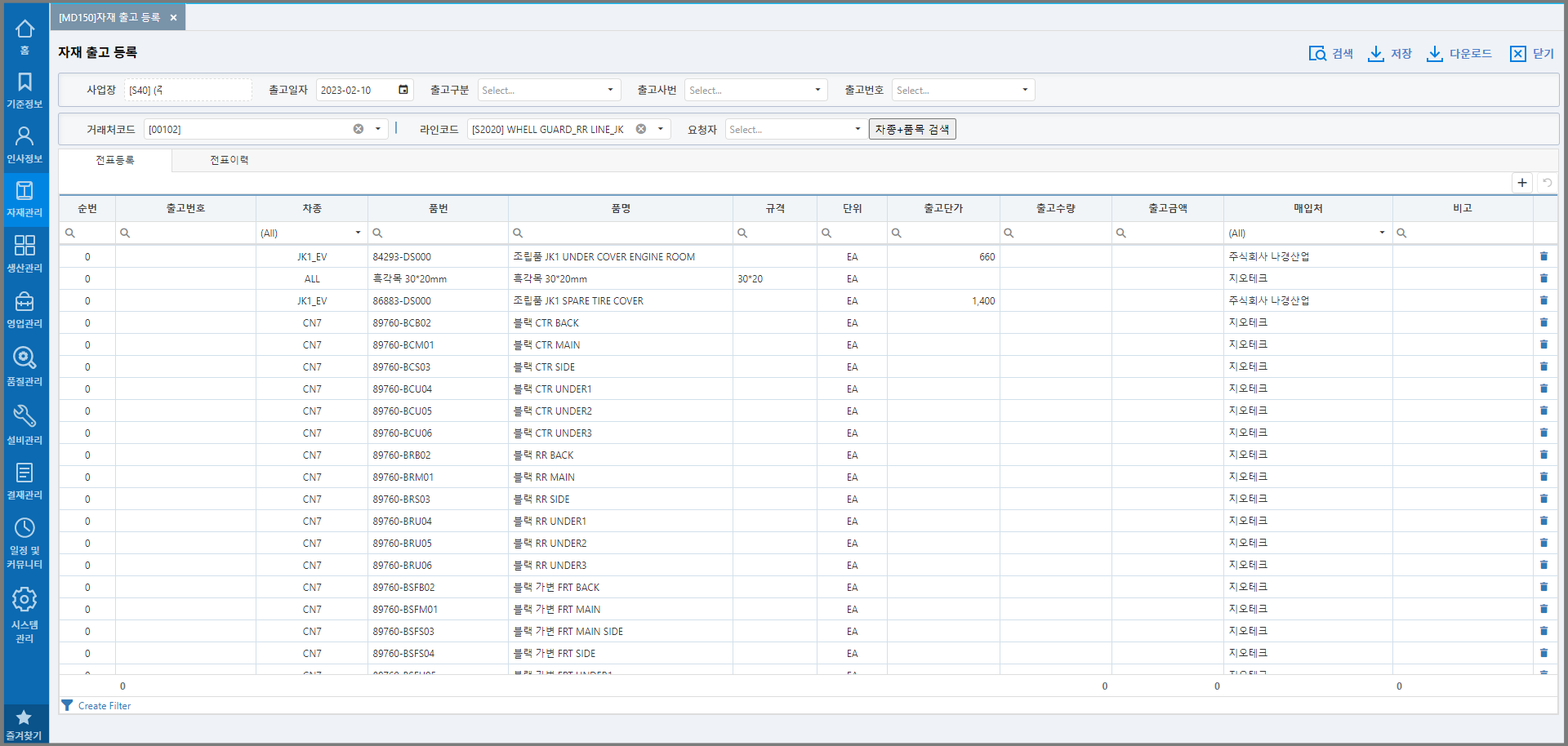

Material forwarding registration

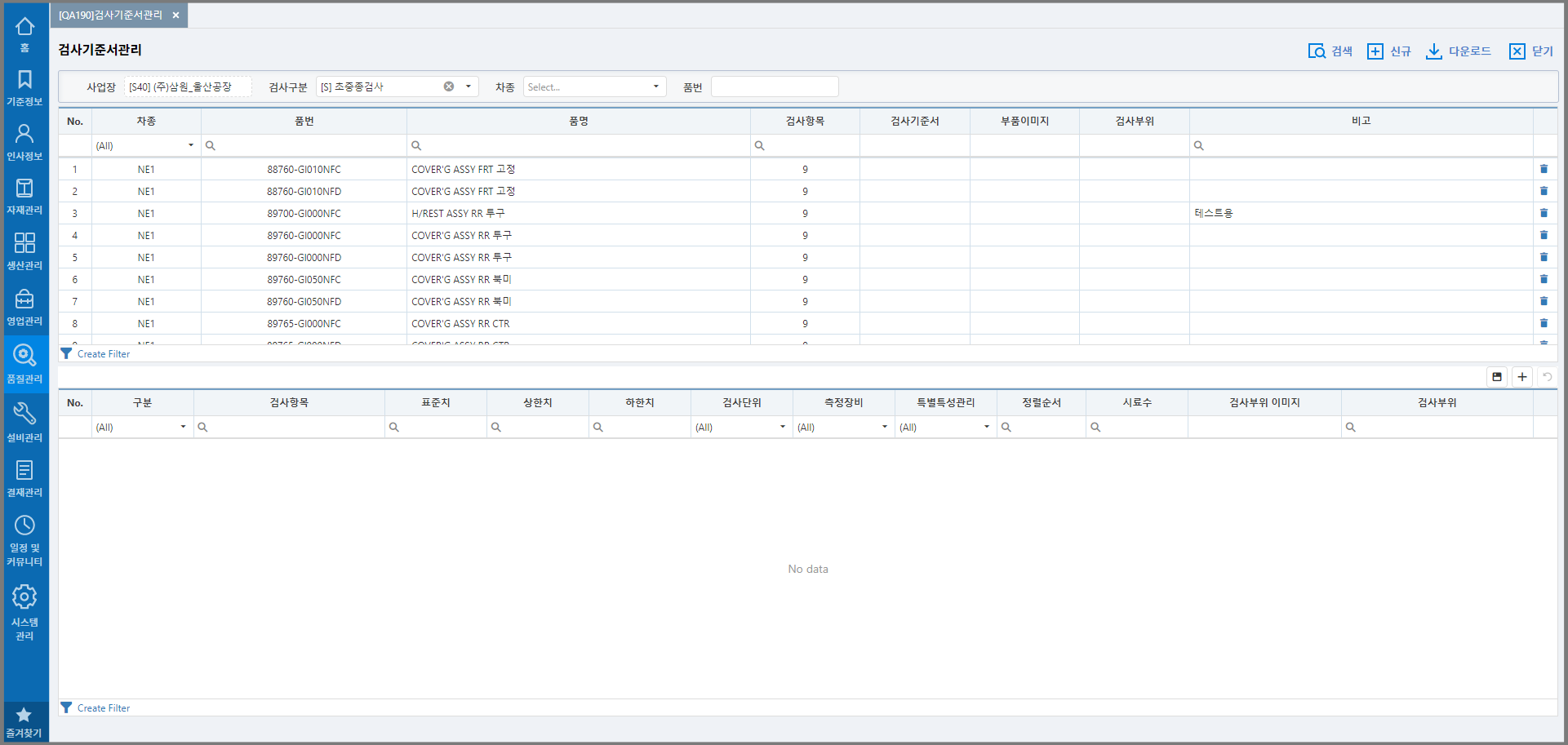

Inspection standard management

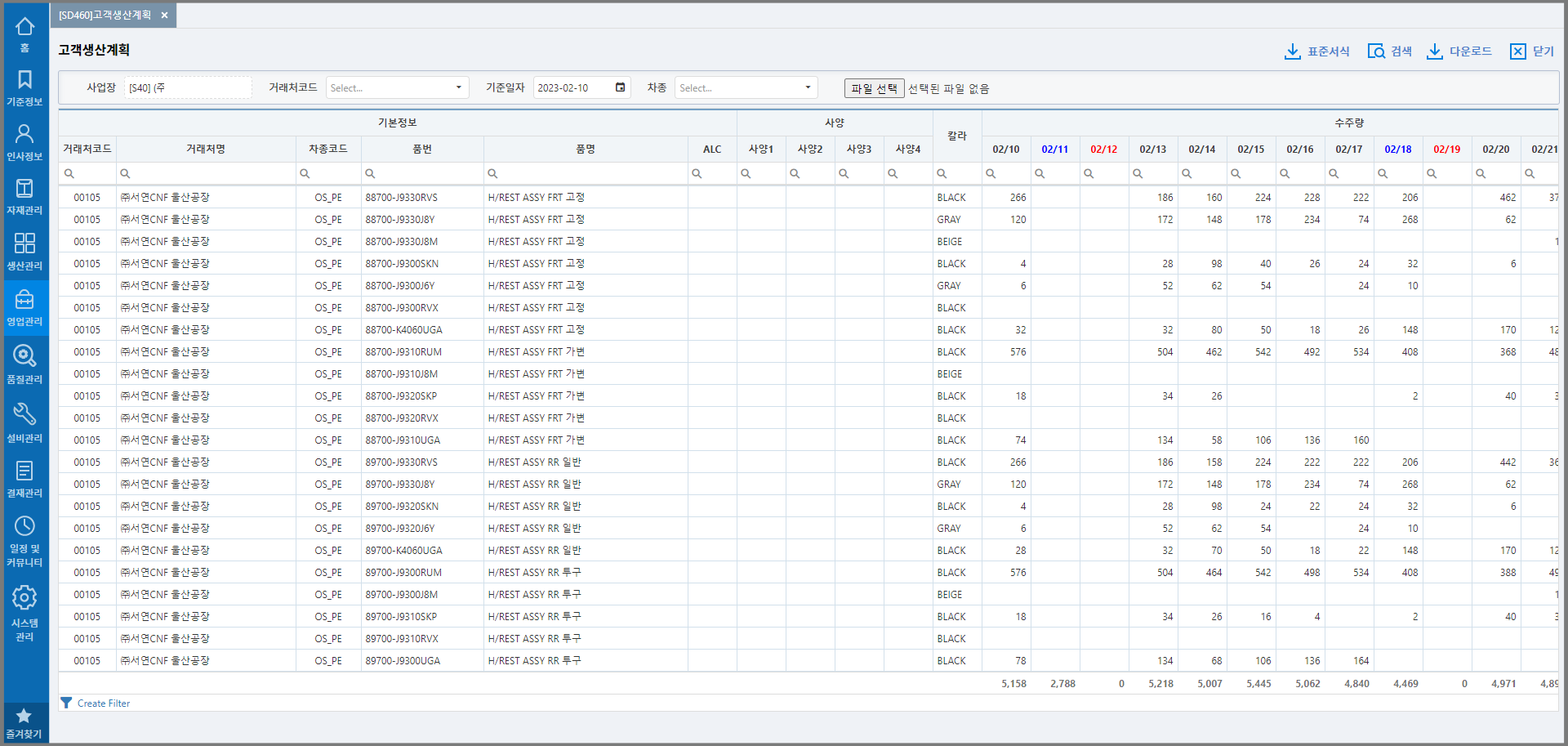

Customer production plan

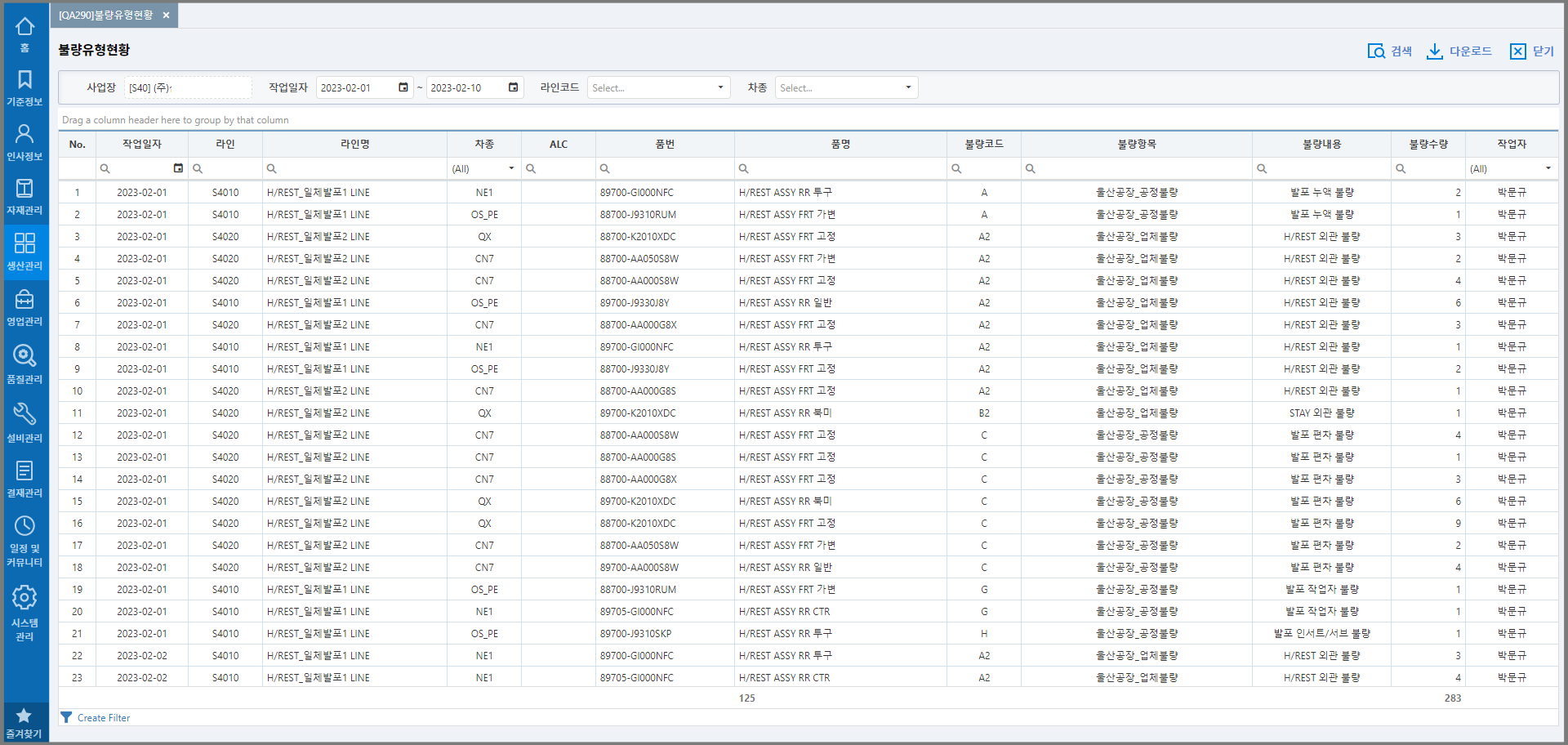

Defect type status

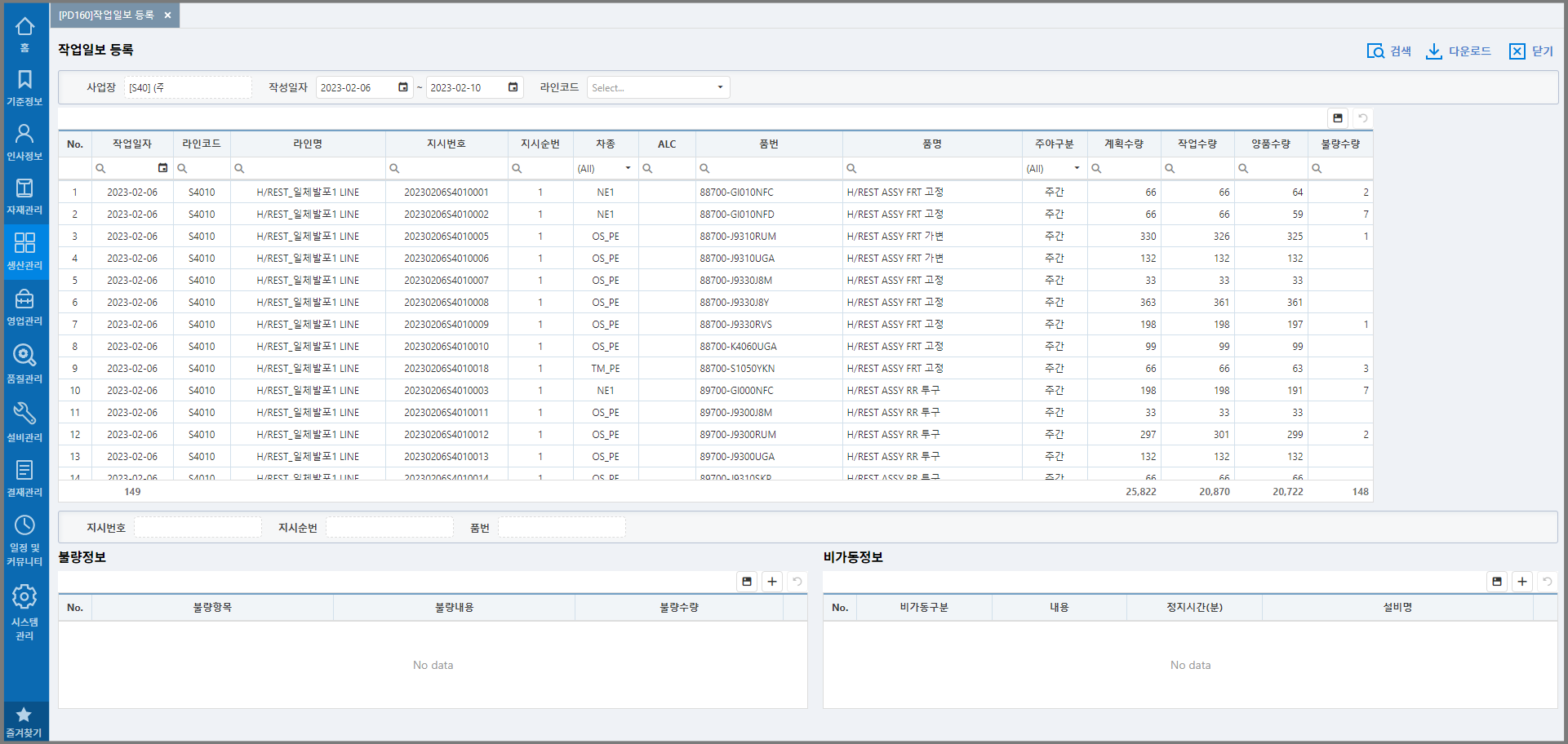

Job Daily Registration

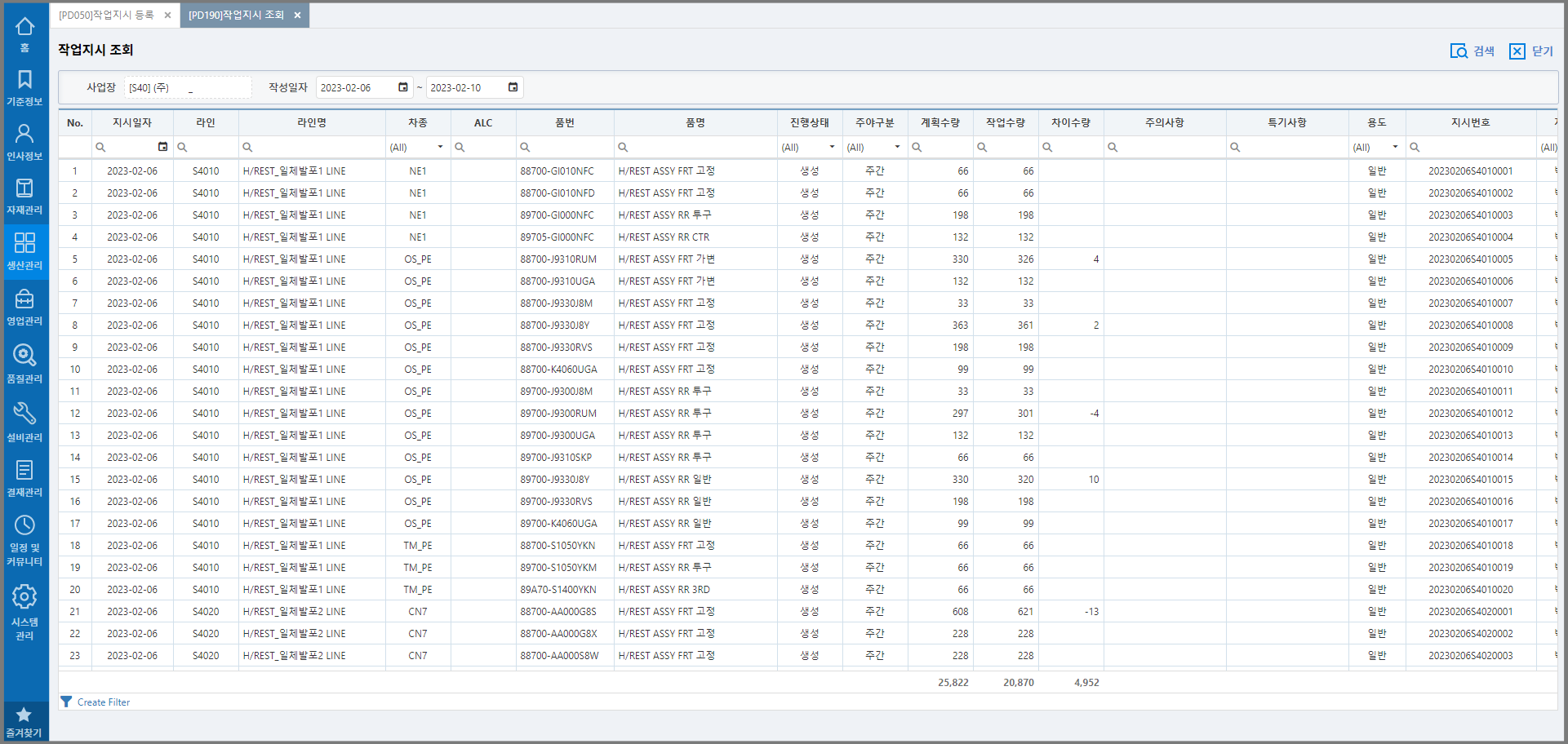

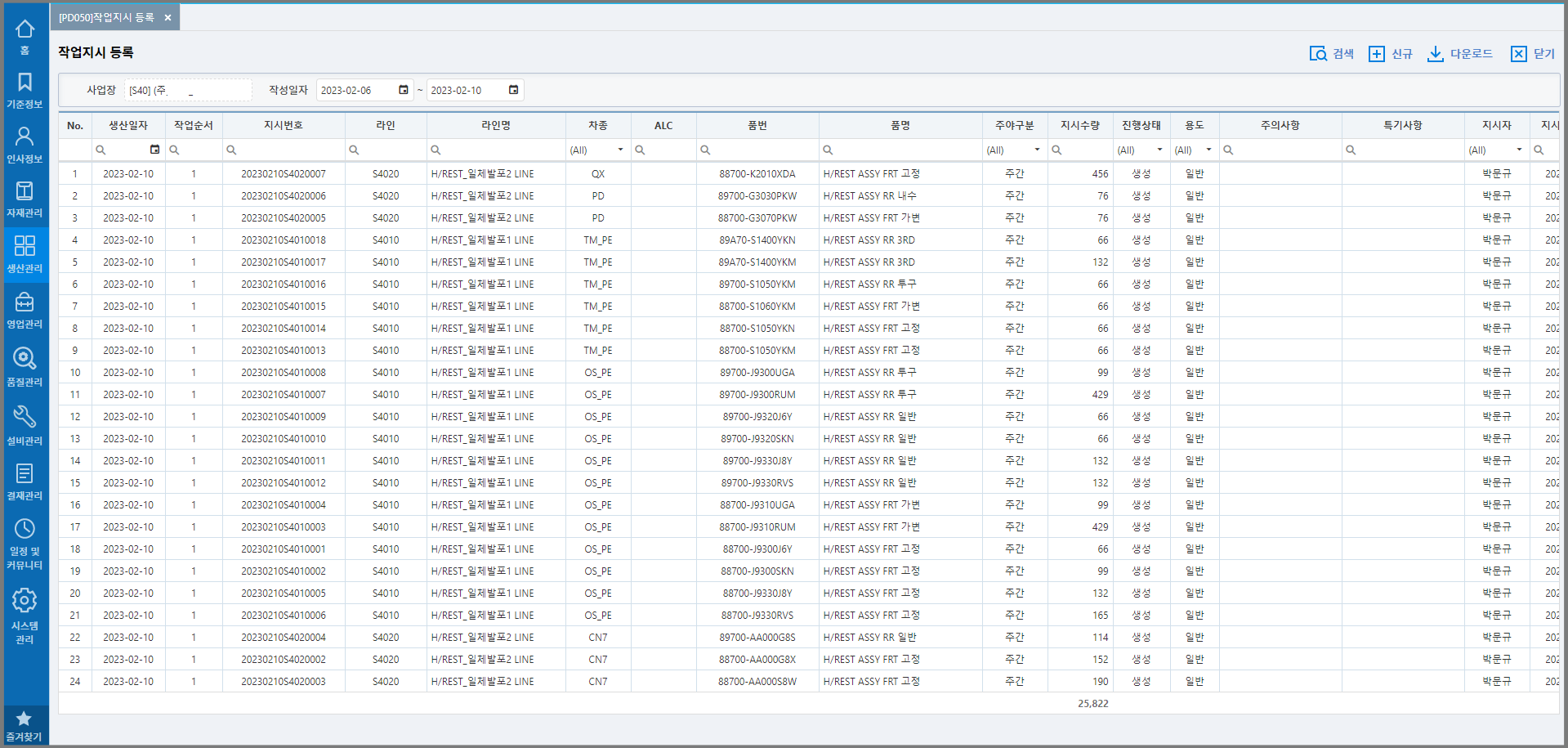

Operation instruction inquiry

PDA operation instruction registration